Sommersemester 2021, BA/MA Textil- und Material-Design Bauhaus 4.0 , Textil_Startseite

Bauhaus 4.0: Fibrous Systems

Project supervision: Agata Kycia, Jörg Hugo, Andrea Rossi

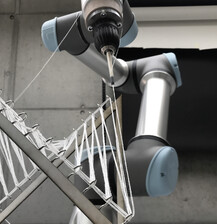

Recent developments in computational design and robotic manufacturing open up new possibilities for production and materialization, challenging designers to reconsider the entire design-to-production chain. Initially developed for factory automation, industrial robots revolutionized creative disciplines where architects, artists and designers constantly push the limits of what is possible. Beyond the automation of traditional fabrication techniques, robotics offer the opportunity to explore and experiment with new, adaptive production methods. Such robust and flexible nature of robotic fabrication finds applications in the textile industry, creating new possibilities for fibrous manufacturing processes.

This semester we explored the possibilities of fibrous robotic manufacturing as well as related concepts of mass customization and digital crafts. Traditional textile manufacturing techniques such as winding or felting were be re-interpret through experimental prototyping and robotic fabrication. We challenged the existing definitions of fibers and learned from existing textile techniques to develop new fibrous systems through continuous production processes.

We experimented with processes such as spatial fiber placement or winding as a way to develop new techniques for textile constructions. Usually, robotic fibrous constructions are put into a form and stiffened by resin and therefore bereft of the intrinsic properties of the fibers such as softness and flexibility. In this project, on the contrary, we explored fibrous structures by embracing the material characteristics of fibers, whether they are soft or hard, elastic or firm, smooth or rough.

Finally, we experimented with the materiality and scale of fibers, challenging their proportions and observing how certain material characteristics affect the production technique. Hands-on experiments and physical prototyping were the core methodologies for the project development.

The Solid Rapid Prototyping Lab with the 6-axis robotic arm was be the place of experimentation and design development, our laboratory and main tool for research and design exploration. Next to the physical experiments and robotic fabrication, new forms of documentation were tested and evaluated, where recorded videos and programming codes are automatically shared on an internal online platform, aiming to exchange knowledge and share experience for future projects.

This project is part of the collaborative, BMBF-funded research project Bauhaus 4.0 by Weißensee Kunsthochschule Berlin (Product Design, Textile-and Surface Design and Foundations) and TU Berlin (Institute of Education, Department of Educational Psychology)

kh-berlin.de/projekt-detail/Project/detail/bauhaus-40-3217.html