Wintersemester 2015/2016, BA/MA Textil- und Material-Design

TUBE TO SURFACE

Building surfaces from circular closed bands

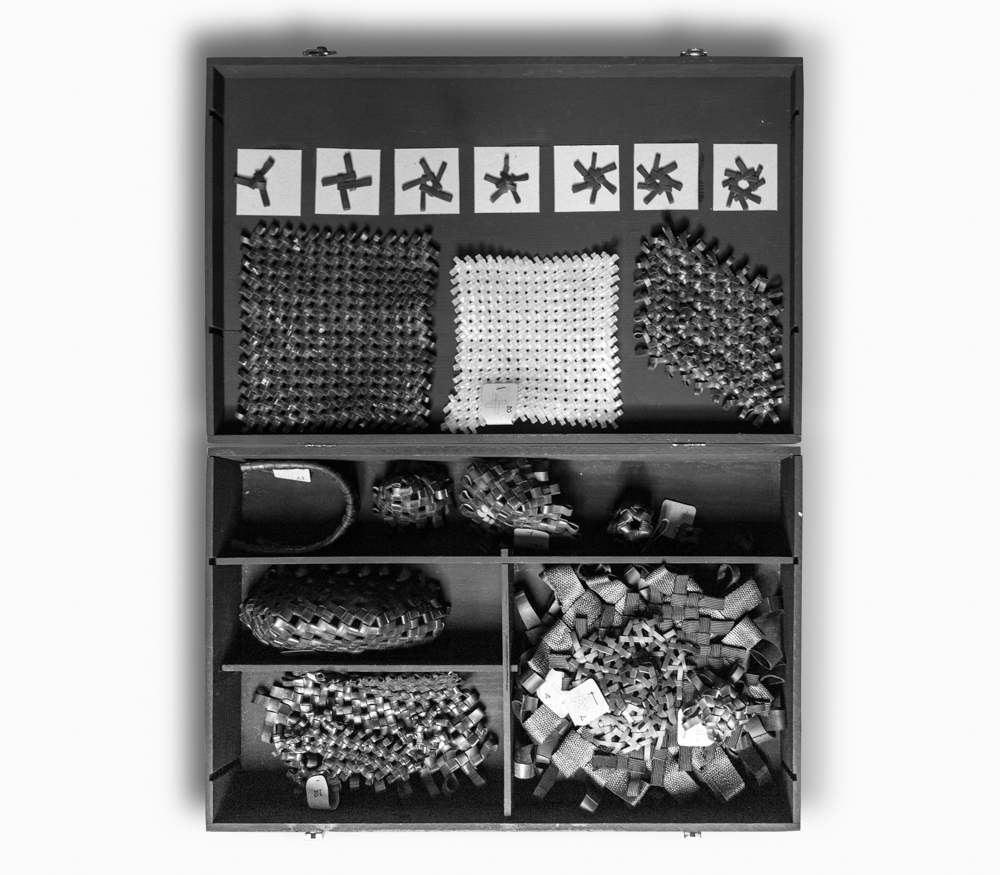

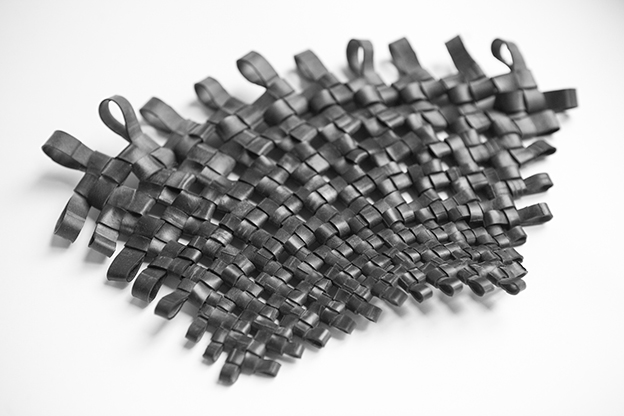

Tube To Surface is a textile design system that uses a circular closed band as a basic modular unit. While being related to weaving techniques, this handcraft allows a large variety of geometrical variations, each of them with distinct technical properties and visual attributes. The result of the research is an archive with a diverse range of surface prototypes that can be built with this system.

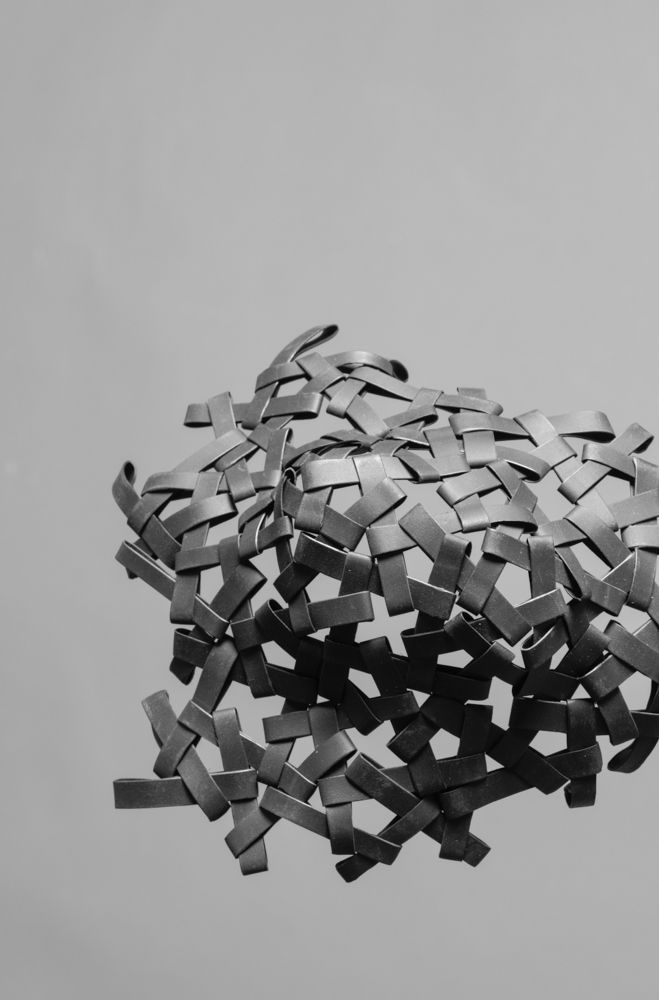

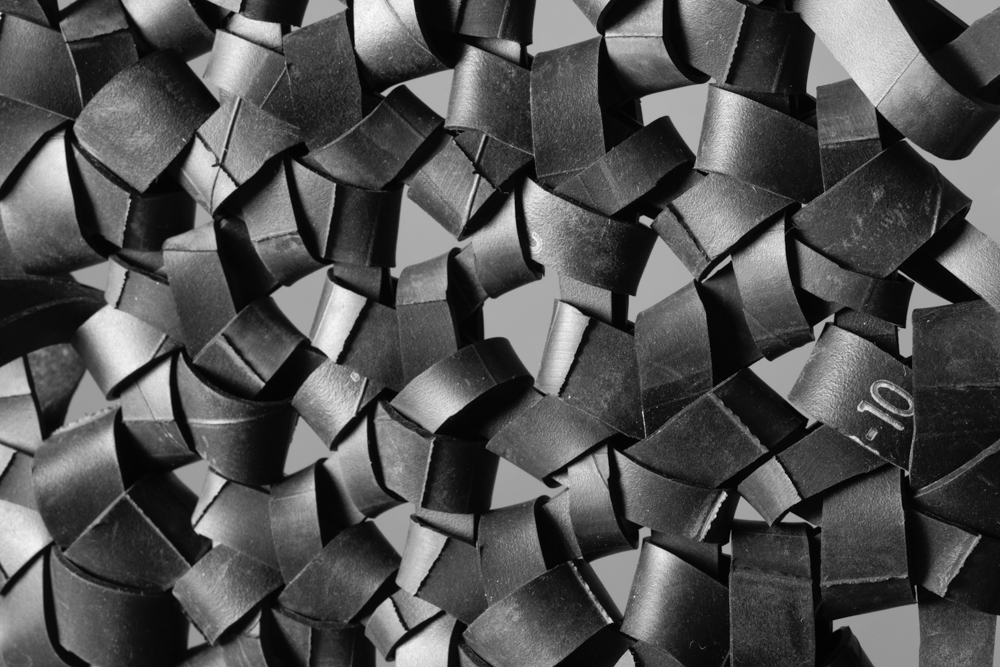

Behind the idea of creating a surface from a tube lied an environmental motivation: Can punctured bicycle tubes be processed and become functional again? Bike tubes are mostly made of Butyl rubber, a high quality, sturdy and elastic material. So slicing them into circular bands and finding a working band-based design system for them was a method to repurpose the tubes into new textiles. As the study has shown, the Tube to Surface technique also works for other kinds of tubes, such as silicone or heat shrink tubing, as these can be cut into the desired size as well. Going beyond the tubular geometry, this handcraft can also be employed with new or discarded textile materials that can be sewn into bands or, even more convenient, that are already produced in bands. The focus of the study has been to explore the geometrical possibilities to attain different surfaces with this simple modular unit.

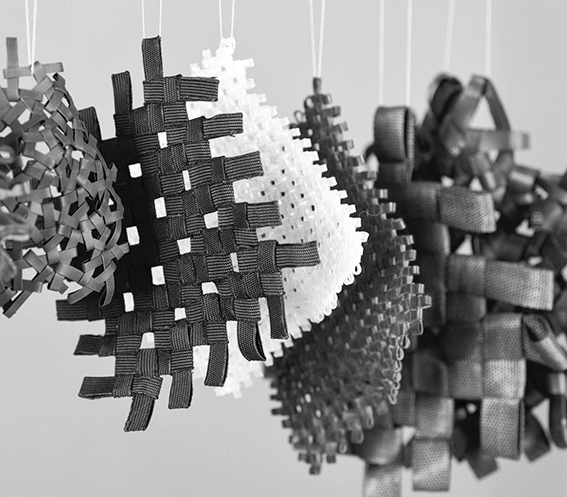

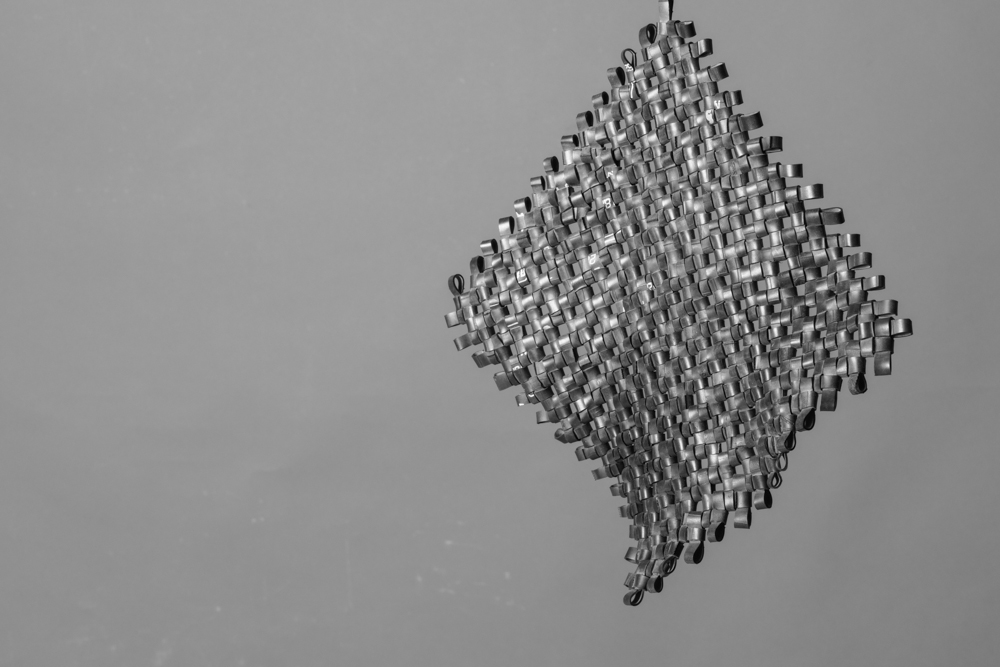

A closed band has three dimensions: length, width, and thickness. These three parameters, along with the chosen material, play a role in the qualities of the resulting surface. Depending on the particular design, the bands can be cut thicker or thinner to allow a tight or a loose weave. The bands can be combined using three, four, five, six, seven or eight bands to form one single knot. Some of these constructions create a flat surface and some of them generate a tension in the material that in turn translates into a three-dimensional shape.

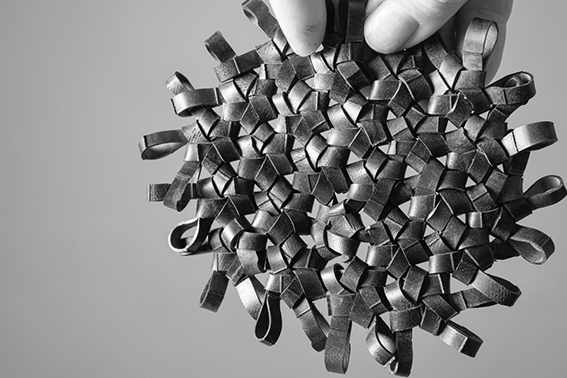

In order to create a surface, the knots are joined with each other so that neighbouring knots share one or more bands. The sets of knots then form a polygon. How many sides the polygon has also influences the behaviour of the resulting textile, whether it grows horizontally or in spherical volumes. In the case of knots with 3 and 5 bands and polygons with 3 and 5 knots usually a three-dimensional surface will be generated.

For instance, using three bands in one knot and combining the knots in polygons of five knots the shape naturally develops into a dodecahedron. To create a corner in a basic flat surface built with knots of four bands and polygons of four knots, a one time knot polygon with three knots can be inserted so that the surface folds 45 degrees and forms an edge. In addition, construction types can be combined to obtain a textile with round and flat parts.

During the research it became apparent that the principles implemented in this textile handcraft are rooted in predetermined natural laws of geometry, which also apply to platonic solids, fullerenes, geodesic domes, modular triangular space grids like the Mero-System and other geometrical constructions. Based on simple units and principles, they offer a high variability in creating modular surfaces of different shapes and properties. Furthermore, the construction of the researched surfaces follows a natural "growing principle".

Due to the robust and sievelike character of the surfaces, when made with rubber they could be applied outdoors as sunblinds or shelters, collection or safety nets and hammocks. When woven with cotton bands they could be used indoors as room separators or as mesh bags.

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat

Alle Rechte vorbehalten Tau Pibernat